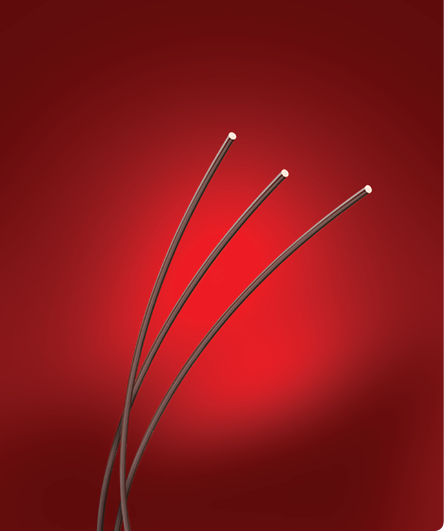

NanoShield SD

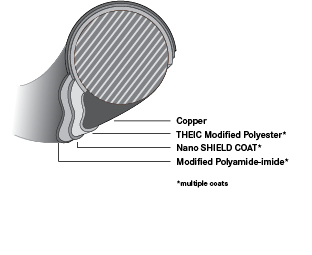

- Exceptional resistance to voltage stresses generated by high frequency, rapid rise time, voltage spikes typically introduced by IGBT-type inverters. Motor life is increased significantly over standard MW-35C magnet wire under these voltage stresses and across a wide temperature range

- Substantial insulation protection against transient spikes, high frequencies, elevated voltage levels, and short rise time pulses without increasing insulation thickness

- Enhanced resistance to thermoplastic flow (cutthrough), surface abrasion and heat shock

- Enhanced Dielectric strength

- Exceptional flexibilty without embrittlement, due to the significant reduction in size of the shield coat particles to the nano level

- Excellent resistance to heat and solvent shock conditions encountered in varnishing and encapsulating processes

- ROHS & REACH Certified

- 100% in-line tested for HVC and bead prevention

150°C, 50% Duty Cycle - Twisted Pairs

18 HTAIH Reference = 600 seconds

18 HTAI NS > 80,000 seconds

50/50 Cellosolve/Xylene

Perchloroethylene

1% NaOH

28% Sulfuric Acid

Gasohol